Attwood Equestrian Surfaces Up to The Challenge

By Elaine Anne Watt

Nick Attwood carries his British heritage well, with the polished manners and modest air so characteristic of his brethren. But, give him a little time to open up about his passion for excellence and commitment to becoming the premier provider of world-class surfaces for equine training and competition, and his initial reticence fades as he describes how he’s made Attwood Equestrian Surfaces the go-to choice for owners of small horse farms or internationally recognized facilities, including some in our own backyard.

Nick’s path to owner, operator and chief marketer of his own company is a true success story built on lessons learned and challenges accepted. Before landing in America in the early 90s, he worked for an English company that specialized in products made from fibers, plastics and polymers. That company bet heavily on textiles made from tencel, an innovative material that was superior to the polyesters currently in wide use; however, the competitive advantages of tencel were quickly adapted to polyesters without the accompanying price tag, relegating tencel use to only the high-end textile market, essentially putting that company out of business. Although Nick had gained tremendous experience working in the product development cycles, the most important lesson proved to be understanding the importance of business practicalities and market relevance.

Nick next moved to a company that developed products for all kinds of sporting surfaces, particularly tennis courts and racetracks. Whereas the climate in England is considered temperate, Nick became the point man for problems that evolved as these products were sold into less stable environments. The product proved to be fatally flawed when used on a racetrack in Oklahoma, where summers are hot and dry and winters can deliver extreme cold. Sent here to oversee and train half a dozen people for the track, he tried to solve the problem of an unsuitable material for the application in use. Ultimately, the equestrian side of that company failed, but it provided an opportunity for Nick to put his problem-solving capabilities to the test.

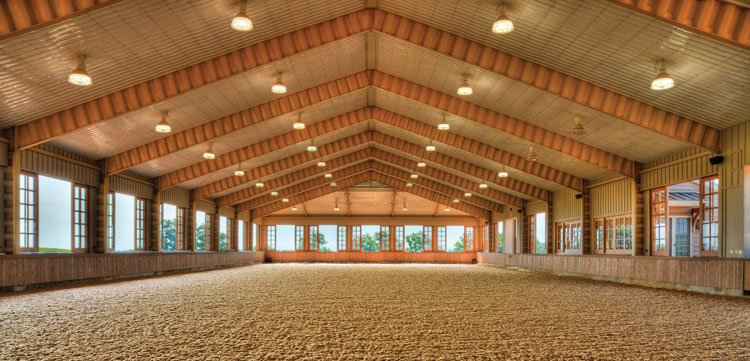

With his background in chemistry, product development and now practical application, Nick went to work to find the right blend of sands, fibers and polymers to create superior footing surfaces for both indoor and outdoor arenas. Attwood offers four options: Pinnacle, Terranova and Ameritrack, which is essentially Pinnacle adapted for racetracks as opposed to dressage or grand prix. The fourth, EuroTex, is a sand and textile formulation that is water dependent and suitable for all riding disciplines. Unlike many competitors’ products, the materials used are non-toxic, do not contain wax and do not become airborne, posing no inherent harm to the animals or humans. Of course, Attwood will propose and select the surface most appropriate to the conditions and purposes envisioned.

Attwood’s products are uniquely designed to optimize the interaction of the horse with the surface, with superior absorption of impact resulting in secure footing and release, all on a dust-free and water repellant surface that provides an evenly engineered consistent plane throughout the arena. The result is the convenience of a low-maintenance, long-lasting equestrian surface for the serious rider, ready for use when needed, and upon which the horse can safely develop musculature and conditioning to prepare for competition with a minimum of risk and reduction in potential injuries.

When asked if this might increase the likelihood of harm on less optimized surfaces, Nick explained that it actually works to the contrary. A well-conditioned and properly developed horse will be able to withstand more challenging conditions than a horse that has not had the benefit of that training; furthermore, with the overall improvement in the surfaces on the competitive circuits, it is no longer hard to make choices to avoid the riskier venues of the past.

His customers really care about giving their horses the best. It is less about convenience than in the beginning when many of his clients wanted the time-saving benefits of his products, allowing for more spontaneous use of their arenas. With the knowledge that has been gained about the wear and tear that can happen with repeated training, an investment in the proper footing reaps huge dividends for both horse and rider.

Gone are the early days when Nick had to perform most of the work himself. He now has a devoted team “that feels like family” with Edwin Barron his second in command, but he will travel all over the country and the world to supervise the projects. In addition to local projects such as Great Meadow, Morven Park and at the “fabulous farms and ranches of Middleburg,” there are now horse arenas associated with most major cities, and Attwood has done installations in 43 states as well as internationally. Developing his employees and being willing to take on projects that are “a little more adventurous” keeps Nick and his team at the forefront of some of the most exciting work in their field.

Currently, they are working in the United Arab Emirates building a racetrack using all American-made coatings on their materials. “It’s kind of neat in a way that we are selling them products made of sand and oil,” he said. He’ll be back and forth during the six-week job making sure that all is completed to the company’s standards.

When asked what some of his greatest obstacles have been, Nick tells the story of how his father made him return an electric guitar he’d bought in his youth for 30 pounds. “I made my own guitar after that, and every struggle I’ve faced has made me more determined to succeed,” he said.

Marketing has not come as naturally to him as other parts of the business because, “British people don’t like to blow their own horns, and I was reluctant to step up and say just how good we really are. I had to get over that to an extent.”

The rest, whether mentoring his employees or finding the best solution for a client’s needs, is what makes him eager for each day to begin.

Recognizing that his is a “relationship business and that every project is unique,” his passion is pushing him to strive for more. “This company is my life and about how I want to live, not about the money. I feel like I’m in a bit of a rush now because I have so much I want to do before I walk away from that last arena knowing that it is as close to perfection as it can be.” ML